Te ayudamos a construirla:

- Conceptualización y diseño

- Modelado 3D

- Análisis funcional

- Valoración técnica

- Usabilidad

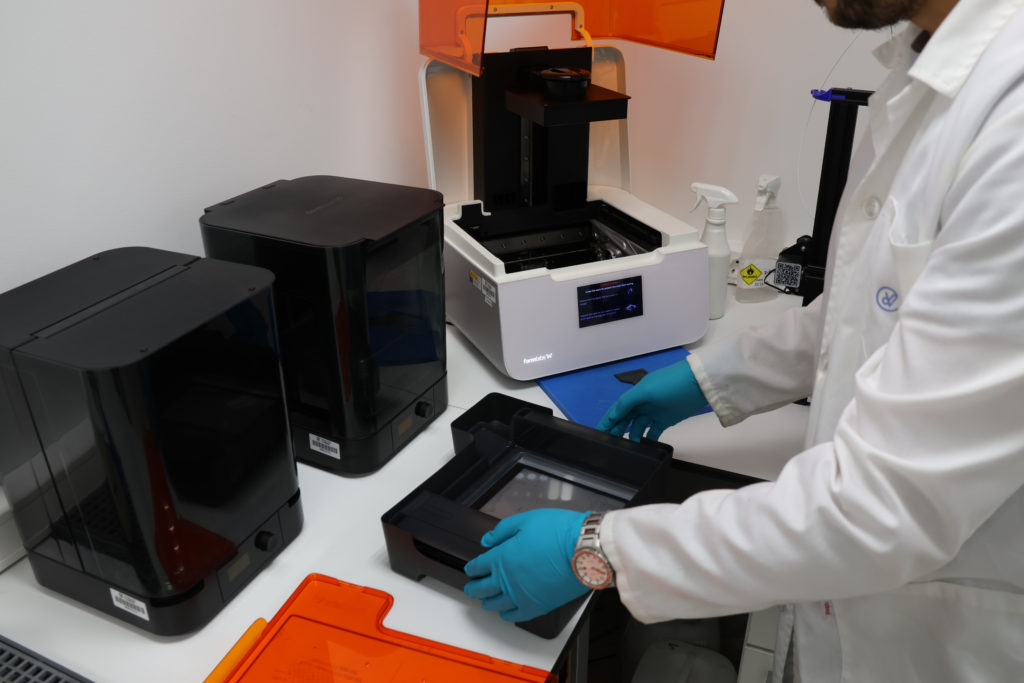

The IDIVAL prototyping unit, established at LINNUX, is the unit responsible for the development of medical prototypes, biomodels and process improvement products in laboratories and services of the SCS, through the use of additive manufacturing.

This process involves designing and manufacturing initial models to evaluate their functionalities prior to production, ensuring they meet safety and efficiency standards. Prototypes allow feedback from professionals, facilitating rapid and accurate prototyping and consultancy, speeding up development and reducing costs.

Creating adaptations for existing tools or equipment with 3D printing improves the functionality and accessibility of products already in use. This process enables the design and manufacture of customised parts that optimise ergonomics and performance. 3D printing facilitates the fast and cost-effective production of adaptations, allowing iterations as needed.

Medical segmentation divides medical images into specific regions representing anatomical structures, facilitating clear and detailed visualisation. These segments can be converted into accurate 3D models, allowing healthcare professionals to examine anatomical structures from multiple angles.

3D modelling from medical segmentations is particularly useful in surgical planning, as surgeons can visualise and plan procedures more accurately. It is also used in the creation of custom prostheses and in medical education, where 3D models provide an interactive learning tool.

3D modelling allows the creation of three-dimensional representations of objects in a digital environment using specialised software. This technology is used in a variety of fields, revolutionising product design, visualisation and manufacturing. In engineering and architecture, it facilitates prototypes and detailed plans. In medicine, it helps in the planning of surgeries and the fabrication of customised prostheses. 3D printing converts digital models into physical objects, essential for rapid prototyping and customised products.

Resin and filament 3D printing are both additive manufacturing techniques, each with specific advantages. Resin printing, using stereolithography (SLA), solidifies liquid resin layer by layer with UV light, producing high-resolution, detailed parts. It is ideal for precision medicine, dentistry and detailed prototypes.

Filament printing uses fused deposition modelling (FDM), where thermoplastic filaments such as PLA, ABS or PETG (each with different physical properties) are melted and extruded layer by layer. It is known for its versatility, accessibility and low cost, suitable for functional prototypes and final parts.

The choice between resin and filament depends on the precision, material and budget of the project: resin offers greater detail and surface quality, while filament is cheaper and faster for larger projects.

3D printing of biomodels is an innovative application in medicine and biology, using medical imaging data to create three-dimensional models of anatomical structures. These models are essential in biomedical research to study diseases and develop treatments.

Our specialist 3D printing and prototyping materials team offers advice on the selection and application of materials for various design and manufacturing needs. Technical expertise is combined with an in-depth understanding of the characteristics of the materials available, providing recommendations from the choice of the right material to the optimisation of printing parameters as well as the use of other prototyping materials such as silicones or resins.

We offer specialised capabilities in the design and development of prototypes for mechatronic healthcare applications and devices. Our expertise encompasses the combination of mechanical components, electronics and advanced programming to create innovative and functional healthcare solutions.

1. Contact us:

Get in touch with our team or fill in the service request form. We are here to listen to you and help you with whatever you need.

2. Tell us your idea or need:

Once you have contacted us, our team will listen to you to understand your idea, requirements or specific needs. We will help you to come up with a solution for your need by approaching it from different perspectives.

3. Solution approach:

With the information gathered, our technical team will analyse the possible solutions. We will propose the best alternatives taking into account aspects such as the material, the manufacturing method and the final use of the prototype or device. In addition, we will provide you with an estimate of time and cost.

4. Manufacturing:

With the information gathered, our technical team will analyse the possible solutions. We will propose the best alternatives taking into account aspects such as the material, the manufacturing method and the final use of the prototype or device. In addition, we will provide you with an estimate of time and cost.

5. Testing and improvement:

With the information gathered, our technical team will analyse the possible solutions. We will propose the best alternatives taking into account aspects such as the material, the manufacturing method and the final use of the prototype or device. In addition, we will provide you with an estimate of time and cost.

Te ayudamos a construirla:

- Conceptualización y diseño

- Modelado 3D

- Análisis funcional

- Valoración técnica

- Usabilidad

If you wish to request a service you must fill in the following form.

If you have any questions, please contact:

Fernando Quevedo Revilla: fernando.quevedo@idival.org

or call +34 942.315.515 (Ext. 79294)

Gerardo García Ruiz: gerardo.garcia@idival.org

or call +34 942.315.515 (Ext. 76225)

Service(€) | Rate 1 | Rate 2 | Rate 3 |

| Basic | 50 | 200 | 350 |

| Medium | 150 | 500 | 750 |

| Advanced | 500 | 1000 | 1500 |

| Expert | Ask |

| PLA Filament (g) | Price (€) | ||

| <150 | 15 | 20 | 90 |

| 150 – 700 | 30 | 45 | 120 |

| >700 | 50 | 85 | 165 |

| PET-G Filament (g) | |||

| <150 | 20 | 25 | 110 |

| 150 – 700 | 35 | 55 | 150 |

| >700 | 65 | 105 | 210 |

| Flex Filament (g) | |||

| <150 | 40 | 50 | 265 |

| 150 – 700 | 85 | 135 | 360 |

| >700 | Ask | ||

| Standard resin (L) | |||

| <0.25 | 35 | 80 | 165 |

| 0.25 – 0.5 | 70 | 135 | 230 |

| 0.5 – 1 | 135 | 235 | 345 |

| Biocompatible resin (L) | |||

| <0.25 | 105 | 130 | 225 |

| 0.25 – 0.5 | 200 | 240 | 350 |

| 0.5 – 1 | 315 | 445 | 585 |

| Other materials | Ask |

Your help allows us to attract research talent to Valdecilla environment and do better. You can help us become better.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.